Contacts:Sales Department

Service hotline:+86 0537-7736666

Tel:+86 0537-7761666

Address:Liangshan Quanpu Industrial Park, Shandong Province

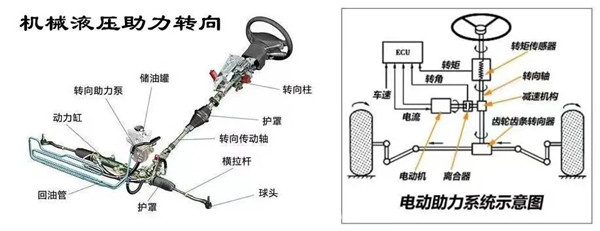

The steering system of automobiles can be broadly classified into two types: electric power steering (EPS), which is generally used for small car models; A hydraulic power steering system HPS, generally used for medium-sized vehicles. There is also an electro-hydraulic power steering system EHPS, which has a wide range of applicability.

Electric power steering (EPS) is divided into seven types, and different new energy vehicle models are matched with different steering systems. They are column type electric power steering (C-EPS), pinion type electric power steering (P-EPS), double pinion type electric power steering (DP-EPS), rack direct power steering (RD-EPS), rack parallel electric power steering (RP-EPS), electric pump hydraulic power steering (H-EPS), electronically controlled variable gear ratio steering system (E-VGR), etc.

The column type electric power steering system (C-EPS) was launched in 1988 as the world's first EPS, based on accumulated technology and experience since production, providing excellent safety, comfort, and environmental performance. The electric power assist device is located on the steering column (inside the cab). Suitable for small and compact cars with small engine compartments, as well as mid size cars. That is to say, new energy vehicle models such as micro cards and small cards.

Small gear electric power steering system (P-EPS) with rack and pinion assistance provides excellent steering feel, high rigidity, and outstanding dynamic performance. By applying mature technology, a steering system with excellent safety, comfort, and environmental performance can be achieved. The electric power assist device is located on the small gear shaft (inside the engine compartment) and adopts a miniaturized design to address environmental issues in the engine compartment. Compared to the column type (C-EPS), the noise reduction effect has been improved.

The Double Small Gear Electric Power Steering System (DP-EPS) is an upgraded version of the small gear wheel type, which separates the electric power steering device from the steering wheel shaft to achieve a flexible and free installation system structure. Adopting an enhanced auxiliary unit design to achieve specific stroke degrees of freedom on the steering wheel side. That is to say, the reduction gear is equipped with a low friction and silent performance anti backlash control system. The installation flexibility has been improved, thanks to the use of orthogonal/cross configuration for the worm gear.

RD-EPS (Rack Direct Assist Electric Power Steering) is a type of power steering system where the rack provides direct assistance to the steering shaft, resulting in a responsive power assist effect. The meaning is to install a power assist unit on the rack shaft. And this power assist unit can be installed at any position on the rack shaft, increasing the freedom of configuration design. The power assist unit adopts a large reduction ratio, which suppresses inertial forces and has excellent maneuverability. The energy-saving system also has lower gear loss and high mechanical efficiency.

The rack and pinion parallel electric power steering system (RP-EPS) fully utilizes over 10 years of RD-EPS mass production experience and adopts high output, compact reduction gears for easier installation. Developed a new ball screw configuration with excellent noise/vibration (NV) performance.

Electric pump hydraulic power steering (H-EPS) is an energy-saving hydraulic electric steering system equipped with an electric pump. It is controlled by a microcomputer and achieves excellent safety, comfort, and environmental performance. The use of a separate electric pump enables extremely flexible installation and the ability for EV driving. By implementing a reasonable oil discharge setting (MAP) and adjusting special valves, excellent steering feel has been achieved and fuel efficiency has been improved. There is also an idle stop mode: it reduces the energy consumption of the car when driving in a straight line by about 80% (10-15 mode) compared to a regular hydraulic power steering system (HPS). Electric pump/ECU (electric hydraulic booster pump) is a helical gear that reduces pulsation and achieves a compact/lightweight design.

The advantage of electric power steering (EPS) is that it only consumes electricity during the steering process, resulting in lower overall energy consumption; It can easily achieve a power assist effect that matches the vehicle speed, balancing the lightness of steering at low speeds and the stability of handling at high speeds, with good centering performance; Simple structure, light weight, easy to arrange, easy to assemble, and easy to maintain; Thoroughly solved the problem of hydraulic oil leakage and followed the trend of "carbon neutrality". The disadvantage is that relying on the control unit to simulate steering feel and force may result in a loss of some road feel; There are many electronic components, and the overall stability and reliability of the system are not as good as mechanical components.

There are three types of hydraulic power steering systems (HPS), namely rack and pinion hydraulic power steering systems, electronically controlled hydraulic power steering systems, and ball screw hydraulic power steering systems.

The rack and pinion hydraulic power steering system provides strong output and strong tracking natural power through hydraulic means, achieving easy and smooth steering. Suitable for a wide range of vehicle models from small cars to RV cars.

The electronically controlled hydraulic power steering system is based on hydraulic power assistance and adds an electronic control system to achieve ideal steering that adapts to vehicle speed.

The ball screw hydraulic power steering system is suitable for ordinary cars, as well as large vehicles such as trucks and buses, providing high output power assistance and a smooth and comfortable collision experience.

The advantage of hydraulic power steering HPS is that the steering wheel is mechanically connected to the steering wheel, which not only provides precise control but also clear road feedback; The power source of steering assistance is the engine, so the available steering power is surging and continuous; Mature technology and high reliability, even if the power assist system fails, the steering system can still rely on mechanical connections for non power assisted steering. No wonder it is still the "darling" of the commercial vehicle industry even today. The disadvantage is that as long as the engine is started, regardless of whether the car is turning or not, the engine is equipped with a hydraulic power pump, which does a lot of useless work and has a high overall energy consumption; The complex hydraulic pipeline structure and numerous oil control valves result in a relatively complex overall structure and require a large assembly space; The entire oil system often maintains high pressure, which can affect its lifespan and pose a risk of hydraulic oil leakage and environmental pollution.

The electro-hydraulic power steering system EHPS is based on the upgrade of HPS, and its basic steering principle is similar to HPS. The main upgrade is the problem of HPS continuously consuming engine power. In EHPS, the hydraulic booster pump is no longer driven by an engine, but by a newly added electric motor. The electronic control unit collects data from wheel speed sensors and other sensors, and after comprehensive processing, controls the opening degree of the hydraulic valve to change the oil pressure, thereby achieving the adjustment of the steering assist force.

Its advantage is that it inherits the precise handling and clear road feedback advantages of HPS; Compared with HPS, it significantly reduces energy consumption; And the power steering can be adjusted according to parameters such as steering angle and vehicle speed, making the response more sensitive. The disadvantage is that it adds more electronic units, resulting in increased overall structural complexity, slightly higher costs, and lower reliability compared to HPS; And the problem of hydraulic oil leakage still exists.

Summary: After reading the above introduction, both hydraulic power steering system HPS and electro-hydraulic power steering system EHPS have the risk of hydraulic oil leakage and environmental pollution; Although there is no oil leakage in the electric power steering system EPS, the steering feel, strength, system stability, and reliability are not as good as the other two. It can be said that there is something good about it!

Admin

There are currently no comments on this content